How Big Food Uses Data Analytics to Understand Customer Preferences

Big food corporations like Nestle, PepsiCo, and Kraft Heinz collect vast troves of data on customers and employ advanced analytics to uncover detailed insights into consumer preferences and behavior. This gives them a competitive edge in product development, marketing, and supply chain optimization. Most all of the major players are investing heavily in data mining and analytical software to derive actionable insights. Through analytics, big food companies break down their customer base into precise segments based on:

- Demographics like age, gender, income, education level, household size

- Psychographics including personality, values, attitudes, interests, lifestyles

- Purchase history encompassing what, how much, when, how often people buy certain items

This enables a nuanced understanding of preferences across factors like taste, packaging, portion sizes, nutritional content, allergens, ingredients, and more. Manufacturers now capture more data to produce oceans of valuable information that gets funneled into predictive models. They gather data in ever increasing ways including: analyzing social media conversations to identify new food trends, surveying shoppers in-store, placing IoT sensors on factory equipment and mining it from consumer loyalty cards.

Predicting Shifts in Consumer Demand

Big food corporations rely heavily on predictive analytics to forecast future shifts in consumer demand. By crunching years of historical purchasing data along with current sales numbers, competitive intelligence, market research, and industry trend analysis, data scientists can build models that predict fluctuations in the popularity of certain flavors, ingredients, packaging types, and products. Companies can use predictive analytics to detect shifts buying patterns so that they can reposition some brands and make acquisitions if needed.

These insights into their customers help big food companies optimize their complex, global supply chains – chains that involve sourcing thousands of ingredients across hundreds of countries. Predictive analytics and demand forecasting give them greater agility to react to expected changes in desired product volumes and availability.

By anticipating consumer preferences 6-12 months out, food manufacturers can finely calibrate production schedules, inventory levels, logistics, warehouses, and more for efficiency. The most sophisticated of companies can leverage data on retail conditions, purchase trends, pricing, promotions, weather variability, and even sporting event schedules to help them with their product inventory planning.

Gone are the days of simple market research. Today’s food companies deploy an intricate network of data collection methods that go far beyond traditional surveys. Smart packaging has emerged as a particularly innovative strategy, with QR codes and Near Field Communication (NFC) tags turning every product into a potential data point. When consumers scan these codes, companies capture valuable information about user engagement, location, and content interactions.

The data collection ecosystem now spans multiple sophisticated channels. Internet of Things (IoT) sensors embedded in manufacturing equipment track real-time storage temperatures and monitor shipment conditions, providing critical insights into product quality and demand patterns. Meanwhile, social media intelligence has become a powerful tool, with companies analyzing conversations on platforms like Instagram, TikTok, and Twitter to track viral food trends and identify shifts in consumer tastes before they reach store shelves.

Loyalty programs have become particularly valuable, gathering precise details on purchase frequency, tracking product preferences, and allowing companies to segment consumer data for increasingly personalized marketing approaches.

Predictive Analytics: Anticipating Consumer Desires

Predictive analytics has transformed raw data into a powerful crystal ball for food innovation. Machine learning algorithms can now forecast trends with remarkable precision, enabling companies to anticipate product demand, customize flavor profiles, target specific market segments, and optimize supply chain operations. The rise of plant-based proteins offers a perfect example. Social media analytics helped companies identify this emerging trend long before it became a mainstream phenomenon, allowing for proactive product development and market positioning.

Future Trends: Tech Centric

The future of food data analytics will rely on emerging technologies like machine learning (ML) and artificial intelligence (AI) to enable faster, localized data processing. Blockchain technology will also provide unprecedented end-to-

Machine Learning for Consumer Trend Prediction

end supply chain transparency. These technologies enable deeper insights, faster processing, and more precise decision-making. Here’s a closer look at how they are transforming data analytics in the food sector.

Machine learning algorithms analyze massive datasets in real time, identifying micro-trends that might otherwise go unnoticed. Unlike traditional predictive models that rely on static historical data, ML systems continuously learn and adapt as new data is ingested. This “live learning” allows companies to detect shifts in consumer preferences earlier than competitors. To see how this might work, consider a machine learning model that can analyze millions of social media posts to detect growing interest in exotic flavors, such as yuzu or dragon fruit. With this insight, a company could introduce a new product line months before competitors catch on.

Impact:

- Faster Product Development: By anticipating consumer preferences, companies can launch products ahead of demand.

- Increased Agility: Rapid identification of trends allows companies to pivot marketing strategies or reallocate production resources.

AI-Driven Product Personalization

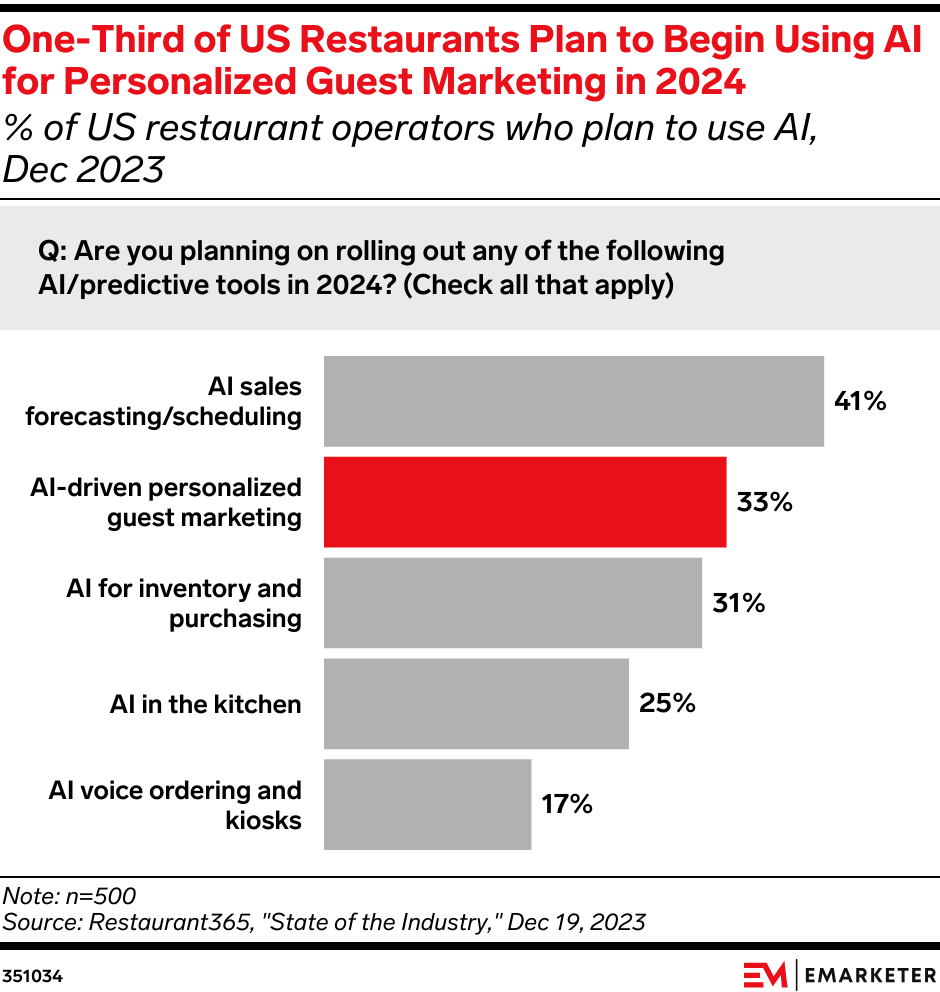

As consumer demand for personalized products grows (e.g., allergen-free, low-sugar, or plant-based options), AI tools will deliver hyper-personalized food experiences. AI systems analyze customer profiles, past purchases, and even individual health data (where legally permitted) to suggest personalized product offerings. For instance, a grocery app may recommend gluten-free or high-protein snacks to a consumer who has previously purchased fitness-related products. AI models factor in not just purchase history but also lifestyle cues, dietary preferences, and seasonal changes.

Impact:

- Personalized Marketing: Retailers can offer highly relevant product recommendations, driving upsell and cross-sell opportunities.

- Consumer Satisfaction: Customization increases consumer satisfaction and brand loyalty, especially in the health and wellness segments

Ethical Considerations: Navigating the Data Landscape

But the use of also AI raises new questions about transparency, fairness, and privacy. AI-driven segmentation and targeting can introduce biases that hurt the company in the public space. For example, if AI models prioritize certain demographics over others, it could lead to exclusionary marketing practices. Ethical AI development will become a key focus for large food corporations.