If you spend enough time in the food industry or if you like reading USDA policy briefs, you’ll hear the words resilience and redundancy tossed around like they’re the same thing. They aren’t. And in the food industry, confusing the two is a recipe for wasted capital and fragile supply chains.

Think of it this way: If one tire on your truck pops and you have a spare in the back, that’s redundancy. If the road ahead is washed out and you have the ability to turn that truck into a boat or find a completely different route via drone, that’s resilience.

As the industry faces more systemic shocks—from climate volatility to labor shifts—understanding this distinction is the difference between a business that survives a crisis and one that folds.

Redundancy: The “Just-in-Case” Safety Net

Redundancy is essentially duplication. It’s the practice of having a “Plan B” that looks exactly like “Plan A.” In our world, that usually looks like:

- Contracting three different suppliers for the same bulk ingredient.

- Building up “safety stock” in cold storage to weather a two-week strike.

- Running parallel processing lines that produce identical SKUs.

The Catch: Redundancy is expensive. It ties up cash in idle inventory and underutilized capacity. More importantly, redundancy only protects you against known risks. It assumes the world will stay the same, but that one specific piece of the machine might break.

Resilience: The Power of the Pivot

Resilience isn’t about having a spare; it’s about adaptability. It’s the system’s ability to absorb a punch, reorganize, and keep moving—even if the environment has fundamentally changed.

True resilience looks like:

- Modular Infrastructure: Processing lines that can switch from retail packaging to foodservice sizes in hours, not weeks.

- Input Flexibility: R&D teams that can swap out a missing stabilizer or oil without ruining the flavor profile or labeling.

- Information over Inventory: Using real-time data to reroute shipments before the port gets congested, rather than just waiting it out with extra stock.

The “Common Mode” Trap

The biggest lesson of the last few years? Redundancy fails when the disruption is systemic. If you have four different suppliers but they all rely on the same specialized ingredient from the same region in Ukraine or China, you don’t actually have redundancy—you have a single point of failure dressed up as a backup.

Redundancy asks: “What if this specific link breaks?”

Resilience asks: “What if the whole chain has to change shape?”

Moving Beyond the Buffer

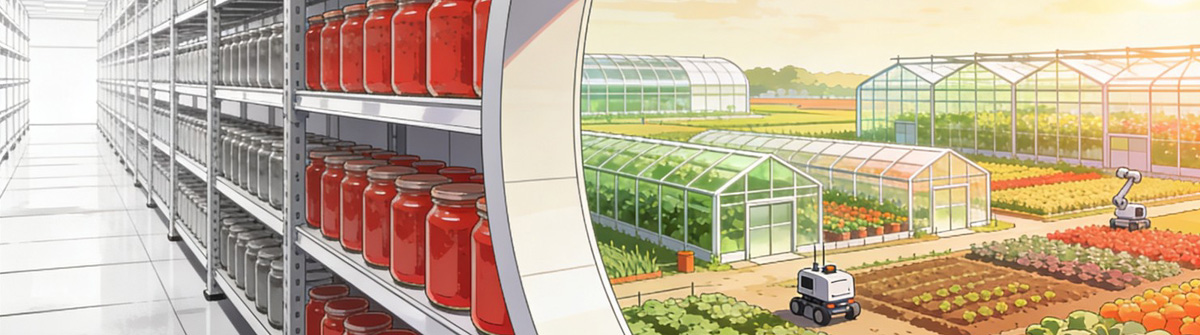

Building a resilient food system is harder than just buying more warehouse space. It requires diversity over duplication. It means favoring regional sourcing networks that operate differently from your national ones, and investing in “smart” tech that allows for faster decision-making.

In the short term, resilience can look like “inefficiency.” It’s slower to build and harder to measure on a quarterly P&L. But as shocks become the new normal, redundancy will only buy you time. Resilience is what buys you a future.

Want to dive deeper into food system dynamics? Check out our latest breakdown on how we categorize the industry to see where your business fits into the resilience map.