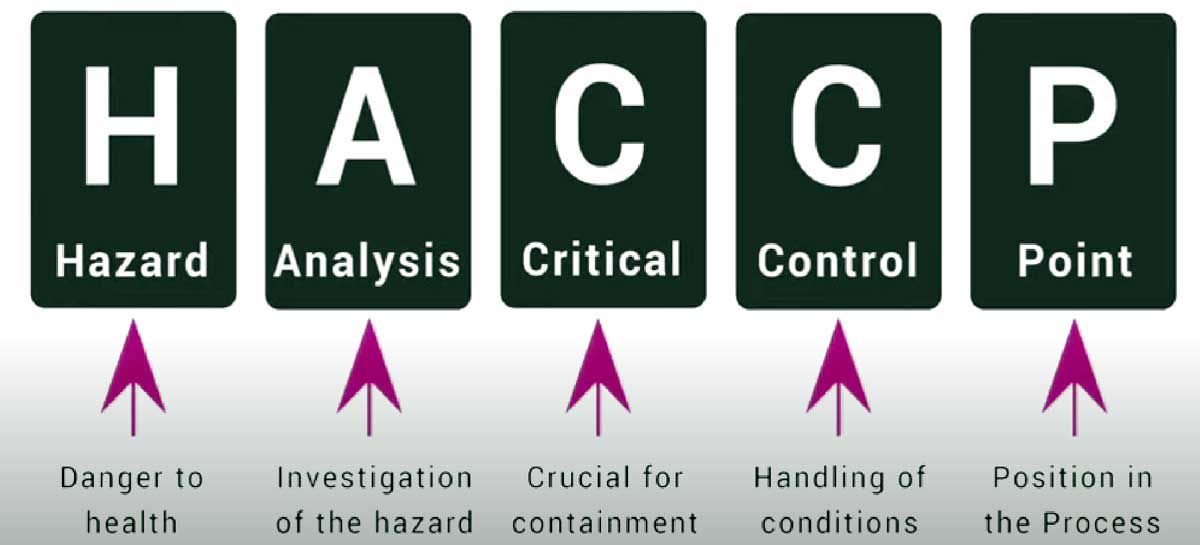

HACCP is a systematic preventive approach to food safety. It identifies physical, chemical, and biological hazards in production processes that can cause the finished product to be unsafe. By controlling these hazards, it minimizes the risk of foodborne illnesses. HACCP is a fundamental component of food safety management.

HACCP is widely used in most of the industries sectors, including: meat and poultry processing, dairy and egg production, seafood processing, fruit and vegetable processing and food service and restaurants. The effectiveness of HACCP lies in its seven principles:

- Hazard Analysis: Identifying potential hazards that could occur in the food production process.

- Critical Control Points (CCPs): Determining points in the process where the identified hazards can be controlled or eliminated.

- Critical Limits: Establishing maximum or minimum limits at each CCP to control the hazard.

- Monitoring Procedures: Implementing procedures to monitor the CCPs.

- Corrective Actions: Establishing actions to be taken when monitoring indicates that a CCP is not under control.

- Verification Procedures: Applying methods, procedures, tests, and other evaluations to ensure the HACCP system is working effectively.

- Record-Keeping and Documentation: Keeping detailed records to show that the HACCP system is effective and being followed.

The Importance of HACCP in the Food Industry

The Hazard Analysis and Critical Control Point (HACCP) system is critical to food safety management across the industry. By taking a preventative approach focused on controlling discrete points in production processes, HACCP helps avoid potentially hazardous contamination issues. Implementing HACCP plans allows food businesses to comply with regulations in many countries that mandate such systems. Beyond legal compliance, effective HACCP programs build consumer trust by demonstrating a strong commitment to producing safe products. Streamlining procedures to focus monitoring and interventions at critical areas also improves production efficiency.

Implementing HACCP systems requires careful planning and preparation. Businesses must assemble a knowledgeable HACCP team comprising expertise on their specific products and processes. This team thoroughly describes all aspects of the food, its intended use, and distribution chains. They clearly define the expected consumer groups for the products. Detailed flow diagrams outline each process step and the product’s progression through the production system. Using these diagrams, potential hazards are identified through methodical hazard analysis at each stage. The HACCP decision tree tool then determines the Critical Control Points (CCPs) where hazards must be controlled. For every CCP, businesses establish associated critical limits, monitoring procedures to assess compliance, and corrective actions in case of deviations. Once implemented, the overall HACCP plan undergoes verification and validation to ensure it works effectively as designed. Careful documentation of all HACCP processes and record-keeping demonstrates due diligence in maintaining compliance.

Challenges & Opportunities

Despite its many benefits, putting HACCP into practice can prove challenging. The complexity of food production chains, specialty ingredients, and customized processes requires uniquely tailored HACCP plans. Personnel must receive proper training in applying HACCP principles to their specific products. Maintaining effective systems also requires constant diligence in monitoring CCPs and verifying control methods. However, the vital importance of food safety makes overcoming these challenges critical.

The future of HACCP includes the integration of digital tools for monitoring and data analysis. We expect that Artificial Intelligence (AI) will present new opportunities and will ultimately change the HACCP landscape. AI will be able to monitor and analyze critical points in the food production process, identifying potential hazards like contamination or temperature deviations in real-time.